Introducing and combining five PV module innovations applied to c-Si based bifacial modules and CIGS modules.

Scope

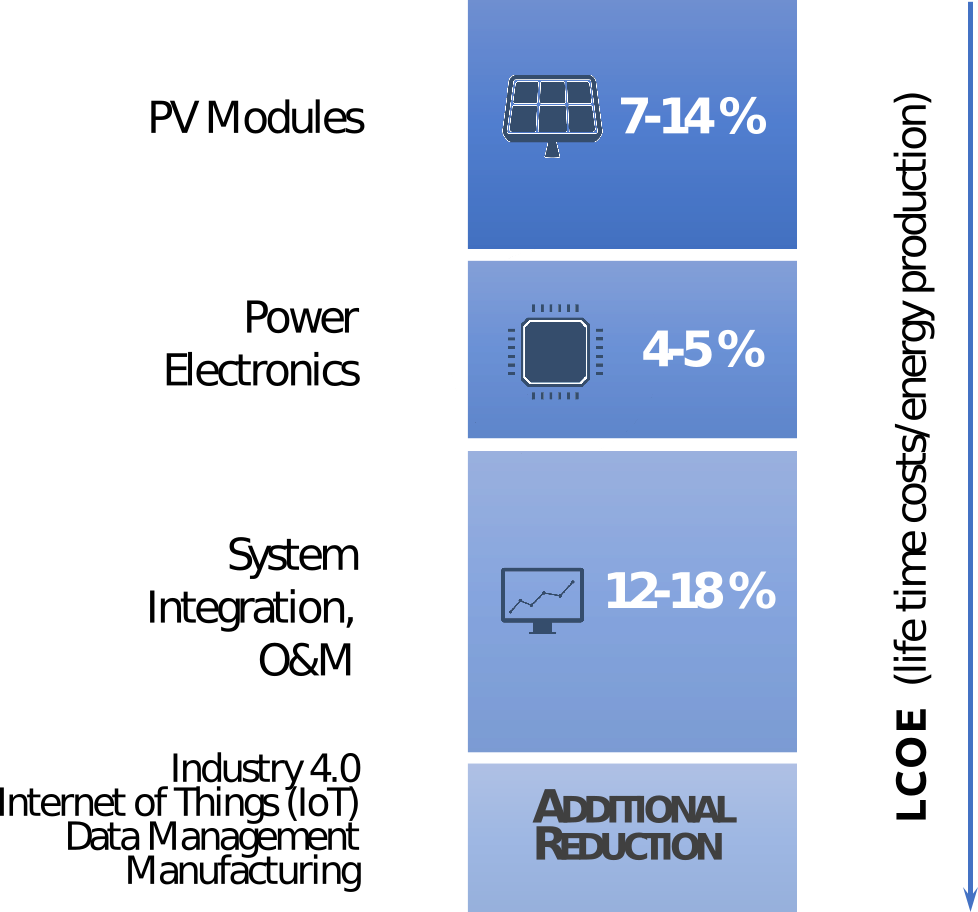

SUPER PV project targets a significant LCOE reduction (26%-37%) for European-made PV by tackling in an integral way three cornerstone steps:

a) Module;

b) Power electronics (PE);

c) System integration / O&M.

Module

Power electronics

Ensuring higher power output, performance monitoring and data collection on string level, and long-term stability of operation

System integration / O&M

Developing a new digital and holistic process:

PIM (PV information Modelling / Management)

Methodology

Proposed innovations and Expected Impact

PV module innovations

Proposed innovation are (i) a combination of anti-Soiling (AS), anti-reflection (AR) and infrared (IR) reflection coating based on nanoparticles, which aims to increase the annual yield of the PV modules; (ii) a white reflector applied to the module’s rear glass within the cell gaps, which improves the light harvesting for the bifacial PV modules, and a deeply structured rear glass to increase light collection from the module rear side and to increase the thermal convection cooling to the surrounding air; (iii) implementation of in-laminate bypass diodes made with solar cell processing machines, which allow omitting the junction box and requiring fewer materials for the module production; (iv) application of Aluminium oxide (Al2O3) gas barrier coatings deposited by spatial atomic layer deposition (SALD); (v) demonstration of a laboratory-recycling tool for all considered module types (c-Si and CIGS) to evaluate the possibility to recycle and re-use the module materials.

PE developments

Proposed hardware level innovations are (i) micro-inverters with advanced switching elements based on GaN; (ii) micro-inverters with smart functionality such as active/reactive power generation; (iii) fault-tolerant converter topologies and converter algorithms; (iv) MPP Optimizers or Smart Boxes with Rapid Shut Down (RSD) functionality that represent dramatic increase of Power Plants fire safety, long-term energy yield, module reliability and PV power plant design flexibility, modularity and longer operation times without maintenance.

Integrated Process and Information Management

The main objective will be to adopt digital software and hardware tools ensuring integrated information flow through the PV value chain this way reducing costs related to the PV projects implementation and operation. This will be achieved through: (i) the development of a digital platform for design, simulation and operation supporting the cost reduction of PV systems; (ii) the development of a tool for extending the PIM-based platform functionalities for O&M operations through a Digital Twin Model, continually updated to include the events sustained while in use, thanks to a sensor-enabled digital model that simulates the object in a live setting.